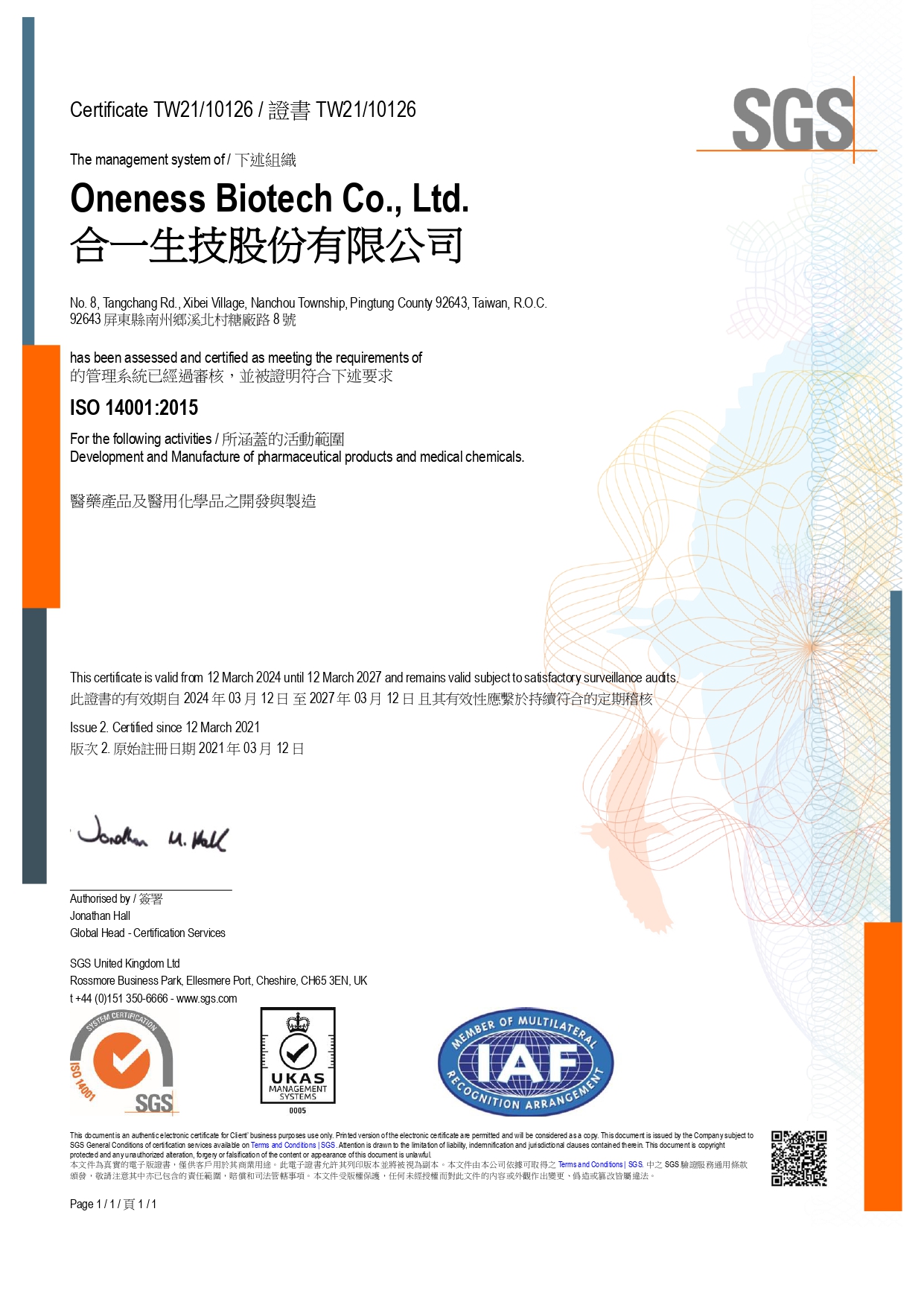

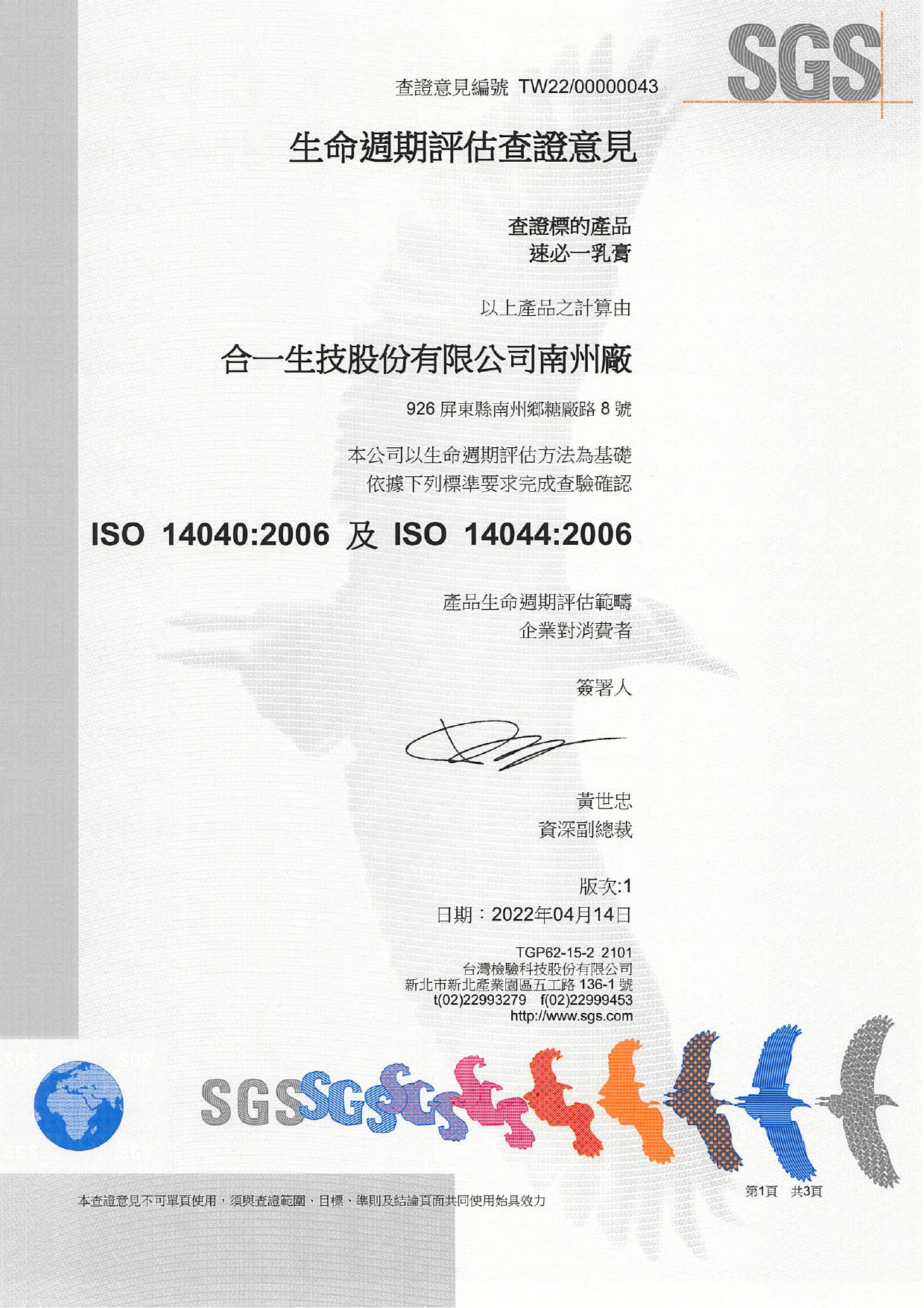

The manufacturing site is located in Nanchou Township, Pingtung County, and has been established on the basis of the sustainable, environmentally-friendly core value. The plant has been ISO 14001 certified in 2021, and the ON101 was ISO 14044, 14040 and 14067 verified in 2022.

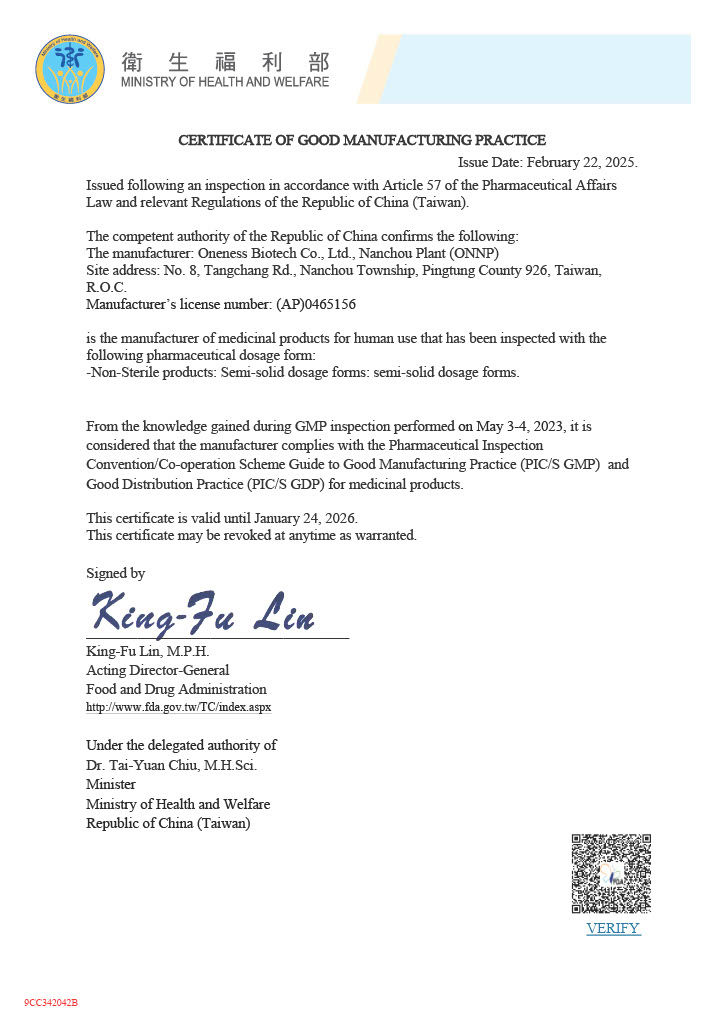

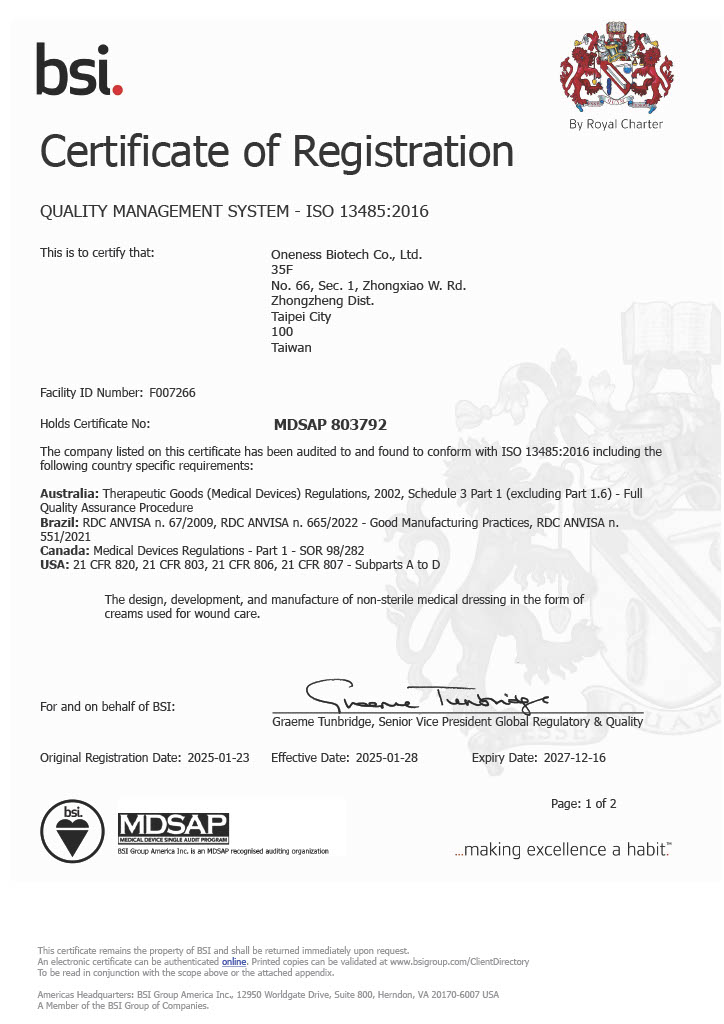

In addition, the Nanchou plant follows the international PIC/S GMP standard. The respective GMP certificates of the drug substance and the drug product and the GDP certificate were granted in 2020 and 2021. The Nanchou plant is also the production site for FESPIXON® cream, the new drug for diabetic foot ulcers. With API and finished product manufacturing capacity as well as the raw material cultivation in compliance with GACP, this plant implemented a streamlined quality control of production from the raw materials, APIs, to the finished product. The ISO 13485 quality system has been implemented to ensure that the quality of development, production, manufacturing of medicinal devices and other related services is complied with the international standard for manufacturing of medical devices.

In order to ensure appropriate and consistent quality of medicinal plant/drug substances, Oneness has established good agricultural and collection practice (GACP) for herbal starting materials. The medicinal plant are under organic and non-toxic cultivation and have to be analyzed by high-tech equipment (GC-MS/MS, LC-MS/MS, ICP-MS, HPLC, etc.) before processing to ensure microbial, heavy metal, pesticide, plasticizer, mycotoxins are within the limits according to the international criteria. The plant is also equipped with temperature-controlled warehouse for the storage of 180 tons of the medicinal materials. This can ensure the quality of the materials and drug safety.

The automatic production facilities minimize the possible errors and pollution by the operation of personnel. The production efficacy and quality can also be improved by having the finished product weighed, printed, and packed automatically.

The planning, production and education trainining at the Oneness Nanchou plant aim to reduce the pollution and burden to the environment. While pursuing growth and developing new business opportunities, it also fulfills the goals of energy conservation and environmental protection, and fulfills the corporate social responsibilities. The Nanchou plant has implemented the construction of a rainwater recycling and storage system to reduce water consumption for recyclability, pollution reduction and energy saving purposes.

The wastewater treatment facilities in the plant use anaerobic biological treatment (UASB) and the BioNET systems developed and designed by the Industrial Technology Research Institute to reduce the use of chemicals and the sludge disposal, and meet the requirements of low pollution and energy saving. The adoption of a new tubular boiler has an energy-saving efficiency of up to 96% and can effectively reduce carbon dioxide emissions. Solvent distillation is recycled and reused for waste reduction and cost reduction.

Sewage prevention and control is an important part of environmental protection. The management of the Nanchou plant for the quality of discharged water is based on “strict pollution prevention and control, implementation ahead of statutory standards, practice of environmental protection, and fulfillment of social responsibilities.” The monitoring activities are as follows::

Click here for the report and data of self-monitored discharged water quality

GMP Certification Issued from the Ministry of Health and Welfare

ISO13485

Medical Devices Quality Management System

MDSAP

Medical Device Quality Management System

Certificate of GMP Compliance Issued by Food and Drug Administration-Philippines

ISO 14001:2015 Environmental Management Systems

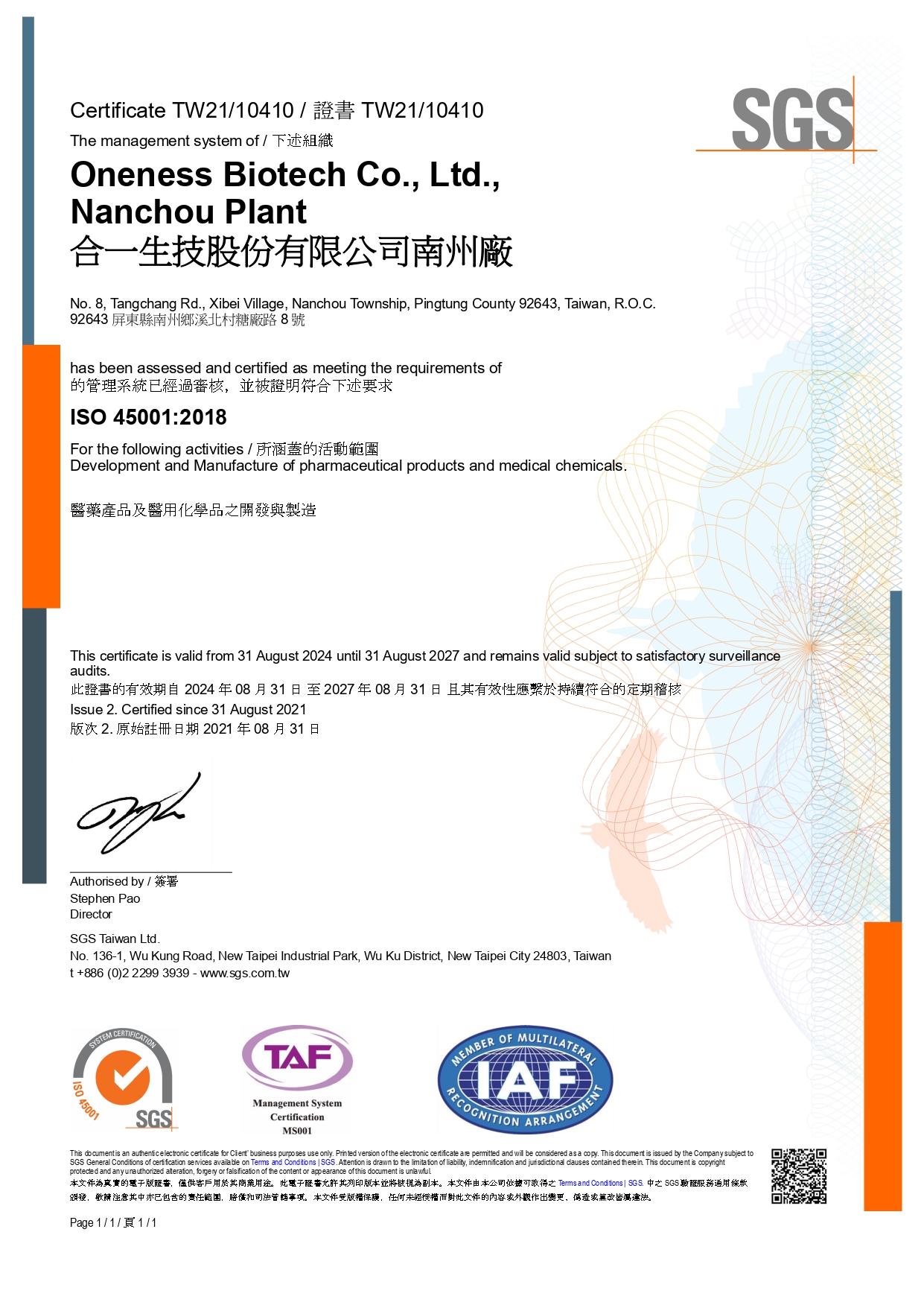

ISO 45001:2018 Occupational Health and Safety Management Systems

ISO 14044, 14040 Life Cycle Assessment Verification Opinion